Quality assurance and compliance are critical aspects of manufacturing, and ERP systems play a vital role in maintaining standards. Integrated quality control features ensure that standard operating procedures are followed at every stage of production, minimizing defects and rework. Furthermore, ERP assists businesses in adhering to tax regulations and industry standards by generating accurate reports and maintaining comprehensive audit trails. The system also provides detailed product costing by factoring in material, labor, and overhead expenses, allowing businesses to set competitive pricing and optimize profit margins

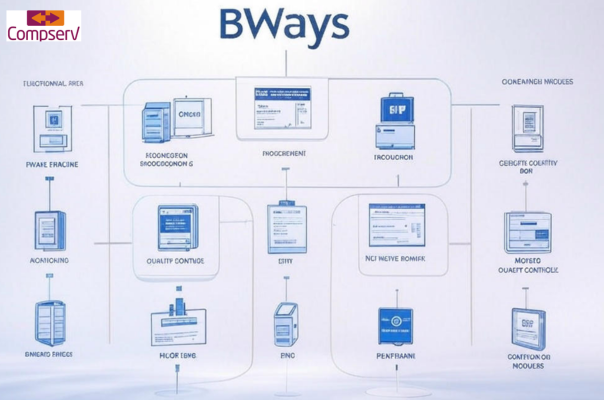

In today’s highly competitive manufacturing industry, businesses face the challenge of balancing efficiency, quality, and cost management while complying with industry regulations. Traditional methods of managing operations through disconnected systems often lead to inefficiencies, miscommunication, and errors. This is where Enterprise Resource Planning (ERP) systems become essential, providing a centralized platform that integrates all business functions, streamlines processes, and enhances overall operational efficiency. By unifying production, procurement, inventory, sales, and finance, ERP ensures seamless communication and data-driven decision-making across departments.

One of the key advantages of ERP is its ability to optimize inventory and production planning. Real-time inventory visibility helps manufacturers prevent both overstocking and stock shortages, leading to better cost management and order fulfillment. Additionally, ERP systems enable precise material requirement planning (MRP), ensuring raw materials are procured on time and production schedules remain uninterrupted. With automated workflows and data-driven insights, manufacturers can eliminate delays, reduce manual errors, and improve resource allocation, ultimately increasing productivity and profitability.